The core focus of customers is the quality of buses, which is also the foundation to achieve the operating income. With consummate manufacturing processes and state-of-the-art technologies, Yutong has realized the perfect combination of safety, reliability, comfort, energy efficiency, environmental friendliness and intelligence so as to manufacture quality buses for you with heart and soul.

Technology

Quality Products

Reliability and Durability

Yutong, your trusted brand

The core focus of customers is the quality of buses, which is also the foundation to achieve the operating income. With consummate manufacturing processes and state-of-the-art technologies, Yutong has realized the perfect combination of safety, reliability, comfort, energy efficiency, environmental friendliness and intelligence so as to manufacture quality buses for you with heart and soul.

All-terrain road simulation test for chassis

The 6-freedom all-condition simulation of wheels can verify the reliability of the chassis framework, axles, leaf springs, airbags, shock absorbers, anti-roll bars and so on.

Road simulation test for whole vehicles

Such destructive tests can greatly improve the reliability of the vehicle and further reduce maintenance costs.

Fatigue test of parts and components

Solve the problems of noise, fatigue and shock resistance performance via tests on the 6-freedom multi-axis vibration bench.

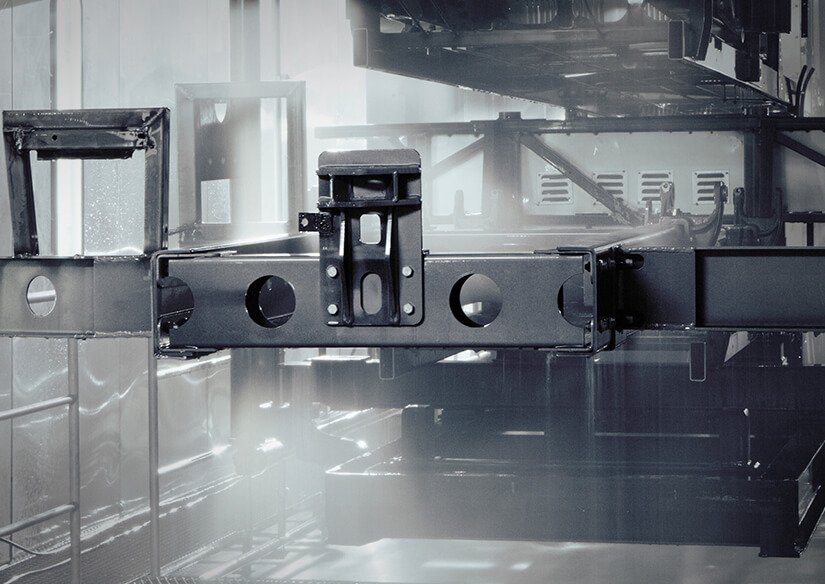

Electrocoating technique

Yutong’s state-of-the-art electrocoating technique greatly improves the anti-corrosion performance and long-lasting beauty of buses. Designed and commissioned by the world-renowned Dürr Company of Germany, the electrocoating line for bus bodies has reached the internationally advanced level in terms of manufacturing process and facilities and taken a lead respecting the scale and production capacity.

Fuel Efifciency

ReCtrl 4.0

The exclusive ReCtrl technology enables plug-in hybrid buses to save fuel by more than 60% and reduce PM emissions by over 90%, leading the technological revolution of energy conservation and emission reduction.

Generation of the engine thermal management system

The 2nd generation of the engine thermal management system self-developed by Yutong can cut 5-10% more fuel consumption of buses than the 1st generation and 10% more fuel consumption than ordinary engines. Meanwhile, it also sees great improvement in terms of stability, fuel consumption, noise and so on.

Whole vehicle / driveline matching technology

Based on the requirements on the vehicle’s power system under actual conditions and through the driveline simulation technology, validation of customer’s operating scenarios and low rolling resistance technology of tires, Yutong has achieved the best optimization of the power system.

Lightweight technology of whole vehicles

The designed weight is about 350kg lower than the products of the same kind, greatly reducing fuel consumption. In addition, corrosion and heat resistance of components is also improved.

Low wind resistance design with CATIA

The wind resistance is about 10% lower than the products of the same kind, greatly improving fuel efficiency and reducing the noise of vehicles.

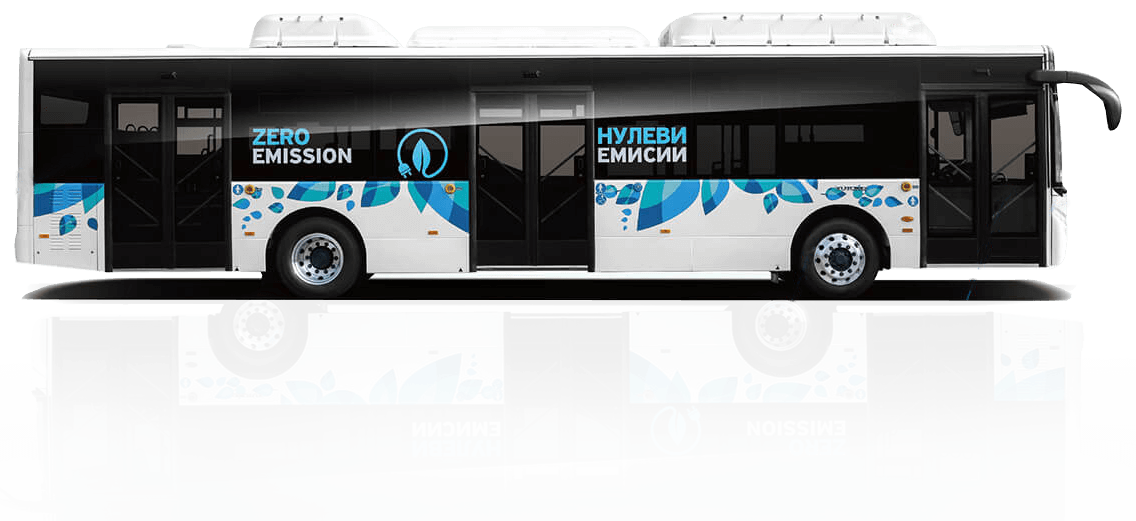

New Energy buses

Yutong always upholds the philosophy of environmental protection and is actively involved in the development of new energy buses. Now the company has fully mastered a number of core technologies of new energy buses and can provide the most suitable mobility solutions for electric buses.

Moreover, Yutong innovatively launched series products of hybrid and full electric buses, and its sales volume of full electric buses was ranked first in the world.

Coverage

Annual sales volume

Total sales volume

3S Safety Technology

Yutong has systematically summarized the technical safety requirements of new energy buses in various operating environments, and proposed “3S Safety Technologies”, which is the latest safety technology of Yutong new energy buses. In order to achieve the three safety goals of “water resistance, fire resistance and electric shock resistance” of the “3S Safety Technologies”, Yutong has deeply studied the material safety, sealing safety and structural safety technologies, and established the safety solutions regarding development & manufacturing, transportation & storage, usage & maintenance, operation & monitoring, etc., comprehensively enhancing the overall safety level of electric buses.

Water resistance

The protection level of the full electric powertrain system meets IP68 requirements and the fording depth of whole vehicles reaches 500mm.

Fire resistance

Buffer spaces for high-voltage electrical components are reserved at the front and rear of the vehicle. Furthermore, the anti-crash structure of vehicle body is enhanced and the high-voltage parts will not be out of function after being collided. High flame retardant grade materials are adopted for the parts of full electric powertrain assemblies. Fully spatial and thermal isolation between battery cabin and passenger compartment poses no threat to passengers even if the batteries catch fire.

Electric shock resistance

No bare wires, terminals or connecting units; Live parts of power circuit system are designed to prevent direct contact; Real-time monitoring system of insulation resistance can trigger visual and acoustic alarm and automatically cut off the power when the insulation resistance value is lower than the warning line.

Battery safety

The batteries have gone through a series of destructive tests such as high temperature, short circuit, squeeze, soak, overcharge, puncture, etc. The battery management system (BMS) can monitor the temperature, voltage, current and electric quantity of each cell, and also has corresponding warning functions.

Recharging safety

Compared to AC recharging, the DC recharging way used by Yutong is much safer, since it is isolated from the grid, and meanwhile has the active and passive protection mechanisms. The max. leakage current of DC recharging is 10mA while the max. leakage current of AC recharging can reach high up to 30mA.

Safety monitoring

Through monitoring the key components, the functions like safety accident prevention, battery life prediction, fault classification warning and so on can be achieved.

Operation case

Santiago, Chile

In January 2018, Yutong’s 12-meter low-floor full electric city bus conducted trial operation on Route 315e in Santiago.

Bulgaria

In 2018, Yutong E12 conducted a trial operation in Bulgaria, which was the first full electric bus in the country. In the same year, a batch of Yutong full electric buses were put into operation in France.

UK

In 2017, a Yutong 12-meter full electric bus conducted trial operation in Liverpool, Manchester and Cambridge for one year with a fault-free record, and the total mileage reached more than 15,000km.

Sofia, Bulgaria

In January 2017, Yutong’s 12-meter full electric bus conducted trial operation in Sofia. When the outside temperature is -20~25 °C, the temperature inside the vehicle can be maintained at 19 °C. The power consumption is quite low, and the driving range can reach 300km after being fully charged.

Macau, China

In 2017, five units of Yutong ZK6109BEVHA full electric coaches successively conducted trial operation in six gaming companies in Macau. In the high temperature environment of 30-35°C and with the air-conditioning temperature at 19°C, the power consumption of these vehicles were excellent. After being fully charged, the vehicle can meet the 16-hour operation requirement.

Yutong full electric bus appeared on UN Climate Change Conference 2015

In February of 2016, Yutong 12-meter full electric bus conducted trial run on Route 21 and 147 in Paris, France and the average speed is 8km/h on Route 21. The driving range of the bus can meet one-day operation requirement while the air conditioner is turned on and the route is congested.

Paris, France

In February of 2016, Yutong 12-meter full electric bus conducted trial run on Route 21 and 147 in Paris, France and the average speed is 8km/h on Route 21. The driving range of the bus can meet one-day operation requirement while the air conditioner is turned on and the route is congested.